How supply constraints stole Christmas from us

Problems with global supply chains are not new, but how did it happen and what does it mean for our Christmas gifts? In this article, we discuss the causes of supply constraints and their impact on holiday shopping.

We got used to the fact that when we order something online, we get it within a few days. This system has collapsed and we must now be patient - says Ole Hansen, director of commodity strategy at the Saxo Bank capital group.

Extreme demand challenges the physical limitations of our world

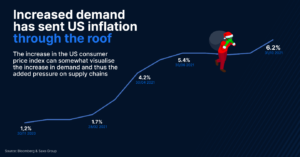

One of the main drivers of supply constraints is the unexpected imbalance between supply and demand in the wake of the Covid-19 pandemic in early 2020. On the one hand, the global economy was forecast to collapse; on the other hand, governments around the world have begun supporting both entrepreneurs and individuals by providing them with financial assistance. The global economy largely did not collapse, and the world went into lockdown, which meant that unexpectedly people had cash, but could not spend it on travel or restaurants, so they began to buy goods and raw materials.

In interviews with the Danish media, I usually say that it all started when we received the statutory holiday allowance from the government, because that's when the shopping frenzy started. Restaurants and cinemas were closed, so we switched to the Internet and started buying consumer goods. Thus, shortly after the cancellation of significant numbers of orders in anticipation of a sharp decline in economic activity due to the pandemic, businesses were suddenly swamped with new orders and the system was unable to meet this challenge. Explains Hansen.

In a world where global activity has already peaked at historically high levels, this kind of spike in demand puts significant pressure on the physical aspects of our ability to deliver the products we procure to customers.

The system Hansen talks about is the logistics sector, where rapid technological advances are beginning to eliminate the physical limitations of our world.

In my opinion, the whole supply chain problem has shown that everything we are talking about is essentially about constraints in the physical world, and if the pandemic showed us anything, it was a phenomenal boom in tech stocks and internet businesses. In my travels and conversations with customers, I show them this graph where we can see that since the global financial crisis, tech companies' revenues and profits have skyrocketed compared to the physical world - the normal world we live in - and recent supply constraints have again shown, that a significant proportion of investment opportunities relate to the digital world Says Garnry.

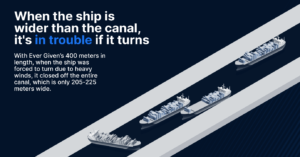

Essentially, this means that because governments were concerned about the economic slump, they began giving money to people and businesses, and they in turn used the money to buy more goods than usual, including technological devices and gadgets, which has increased the pressure on restrictions on physical ships, ports, trucks and roads. In such a situation, the last thing we want is a blockage of the entire system, so the pressure on physical constraints increases even more. One example is the case of Ever Given.

holdup

Let's go back to March this year, when one of the largest container ships in the world, Ever Given, passed through the Suez Canal, one of the world's most important trade routes. Due to strong winds, the ship was forced to turn back and, as a result, got stuck across the Canal. About 400 container ships waited for six days to reopen the Suez Canal, which not only resulted in delays in deliveries, but also further bottlenecks when ships simultaneously entered ports, adding to the pressure on the physical world.

So we have governments handing out money, people around the world eagerly purchasing goods, ports that were already crowded before, and the closure of the global trade route, stopping the normal flow of goods from east to west.

Shortage of people

It can be argued that it shouldn't take long to clear such blockages, as long as everything else works as it should. However, there are two things to understand. First, the transport of goods by sea is steadily increasing, but this is not the case for overland transport.

Container ships are getting bigger, but still one truck is needed to transport one container to and from the port. Therefore, the fact that such ships enter the port and have to be unloaded and loaded in a relatively short time is a growing challenge. This is already a big problem, as we could see in British Felixstowe, in Los Angeles and even in Rotterdam Says Hansen.

At the same time, we have a historic shortage of truck drivers all over the world. In the United States alone, it is estimated that 80 additional drivers will be needed to handle the number of containers that can be delivered to domestic ports. The reasons for this are numerous, but it is an important factor of supply constraints which, moreover, cannot be easily minimized.

Overall, there has been a shortage of truck drivers since the mid-XNUMXs. In addition, many economies around the world are already working at nearly maximum occupancy, which typically allows lower-wage earners - such as drivers - to switch to higher-paying and more attractive jobs due to increased demand for workers. In addition, government support during the pandemic could provide some drivers with funds that they used to get a better job.

We need a lot of truck drivers, which is another problem because there are too few of them. This is mainly due to the fact that some of them have found a different job during the lockdown, and wages are rising in other industries, so employing all the drivers needed to transport all these containers is very difficult. This means that unexpectedly we have a port with an increasing number of empty containers taking up the place of full ones that should go to this port Explains Hansen.

So, with the increase in demand putting pressure on the physical world and the blockage of a significant trade route, there is still a shortage of people and vehicles to handle these containers after the ship arrives in port, contributing to even greater delays and difficulties in global freight transport.

Facilities Closing Due to Covid

When trying to explain how the supply constraints occurred, it is impossible not to mention the Covid-19 virus, as it had a significant impact on it. As already mentioned, one of the responses to the pandemic was government fiscal stimulus, which had a number of minor effects. Concretely, the Covid-19 pandemic negatively affected port operations around the world - particularly in China, one of the world's key production centers.

China's zero-tolerance policy for Covid-19 makes it difficult to keep supply chains running efficiently as in the event of a new wave of infections, the Chinese government tends to shut down large parts of the region where the infections have taken place Says Garnry.

The most important element is missing

The difficulty of transporting goods around the world is a significant challenge. However, the difficulty of shipping the most important element of today's technology products is certainly a much bigger problem.

Semiconductors - also known as integrated circuits or microprocessors - are used in a wide variety of products and goods, with a focus on electronics. The semiconductor shortage - as in the other cases mentioned - is the result of a number of factors, including bad weather conditions in Texas, trade disputes between the United States and Chinaand, above all, the Covid-19 pandemic. This shortage, however, is much more important because it affects the decrease in sales of some of the products for which there is the greatest demand. In this sense, the semiconductor shortage is a real Grinch, stealing our most popular Christmas gifts before they are even manufactured.

The semiconductor shortage affects everything from Nintendo to car and PlayStation production. For these reasons, there was also a reduction in the production of iPhones by as much as 10 million units. So even if we want it, and it's cool, we won't be able to get it Garnry emphasizes.

Likewise, if we want to buy a new car, semiconductors can ruin our plans. Automakers who buy semiconductors at a lower margin have delayed placing orders after the pandemic's economic downturn did not materialize. The semiconductor industry has already found willing buyers due to the high demand for gaming and cryptocurrency graphics cards, as well as microprocessors used in data centers and computers. Car manufacturers are therefore at the very end of the queue and have not yet managed to regain priority status, so car production has been limited due to a lack of semiconductors, which means we have many vehicles almost fully ready for transport, but this cannot be because one essential element is missing Says Garnry.

Centralization of products

When analyzing various causes of problems in the supply chain, it can be noticed that one of them also indicates a potential solution in the form of a massive change in the long-term production strategy. - If we put ourselves today in the place of a large company producing consumer goods, whose main market is the United States and Europe, the question arises whether production should not be moved closer to our sales markets Says Garnry.

He added:

Not so long ago, I had a very interesting conversation with Jens Bjørn Andersen, CEO of DSV, where we discussed this situation. In the financial industry, we always suggest that investors make efforts to diversify their portfolios. However, for an incomprehensible reason, such a concept has escaped the manufacturing industry, as evidenced by production portfolios. In other words, manufacturing companies have shifted a huge proportion of their global output to China, and this proves to be very problematic in disruptions like today. As a result, production may become more fragmented and manufacturers may begin to diversify their supply chains. My bet is that some production will return to the main western consumer markets in the future.

How to steal back the holiday from the supply Grinch?

Although the possibility of relocating production back to the vicinity of the main outlets indicated by Garnry is justified, it is a long-term solution that cannot save Christmas shopping. For now, we have to get used to the idea that getting what we want will be difficult.

We need to restore the supply and demand balance. Until then, we will have to accept, for several years, some disruptions that are causing temporary difficulties in different parts of the world Says Hansen.

Garnry adds that the congestion problem will fix itself: This will happen, but it takes time.

So what are we to do? Even though the Grinch can steal our car, iPhone, or PlayStation, Hansen thinks it's important to go through our letters to Santa Claus and enter something the Grinch can't steal - and so we can do something good.

In the context of Christmas, you can think a little less standard. The recovery of the global economy was very strong, but one area remained in the dark - I am talking about the service sector. So if you can't find the products you wanted, think about services. Request a gift card for a movie, restaurant, or other local service facility. They don't run out of resources, and they might need it - underlines.

More Saxo analyzes are available here.

![Forex Club – Tax 9 – Settle tax on a foreign broker [Download the Application] Forex Club - Tax 9](https://forexclub.pl/wp-content/uploads/2024/02/Forex-Club-Podatek-9-184x120.jpg?v=1709046278)

![Trading View platform – solutions tailored to the needs of traders [Review] trading view review](https://forexclub.pl/wp-content/uploads/2024/03/trading-view-recenzja-184x120.jpg?v=1709558918)

![How to connect your FP Markets account to the Trading View platform [Guide] fp markets trading view](https://forexclub.pl/wp-content/uploads/2024/02/fp-markets-trading-view-184x120.jpg?v=1708677291)

![How to invest in ChatGPT and AI? Stocks and ETFs [Guide] how to invest in chatgpt and artificial intelligence](https://forexclub.pl/wp-content/uploads/2023/02/jak-inwestowac-w-chatgpt-i-sztuczna-inteligencje-184x120.jpg?v=1676364263)

![WeWork – the anatomy of the collapse of a company valued at $47 billion [WeWork, part II] wework bankruptcy story](https://forexclub.pl/wp-content/uploads/2024/04/wework-bankructwo-historia-184x120.jpg?v=1711729561)

![Adam Neumann – the man who screwed up Softbank [WeWork, part AND] adam neumann wework](https://forexclub.pl/wp-content/uploads/2024/04/adam-neumann-wework-184x120.jpg?v=1711728724)

![How to transfer shares to another brokerage office [Procedure description] how to transfer shares to another brokerage house](https://forexclub.pl/wp-content/uploads/2024/03/jak-przeniesc-akcje-do-innego-biura-maklerskiego-184x120.jpg?v=1709556924)

![The most common mistakes of a beginner trader - Mr Yogi [VIDEO] Scalping - The most common mistakes of a beginner trader - VIDEO](https://forexclub.pl/wp-content/uploads/2024/03/Scalping-Najczestsze-bledy-poczatkujacego-tradera-VIDEO-184x120.jpg?v=1711601376)

![Learning patience: No position is also a position - Mr Yogi [VIDEO] Scalping - Learning patience - No position is also a position - VIDEO](https://forexclub.pl/wp-content/uploads/2024/03/Scalping-Nauka-cierpliwosci-Brak-pozycji-to-tez-pozycja-VIDEO-184x120.jpg?v=1710999249)

![When to exit a position and how to minimize losses - Mr Yogi [VIDEO] Scalping - When to exit a position and how to minimize losses - VIDEO](https://forexclub.pl/wp-content/uploads/2024/03/Scalping-Kiedy-wyjsc-z-pozycji-i-jak-minimalizowac-straty-VIDEO-184x120.jpg?v=1710336731)